Magnetic encoders,also known as magnetic encoders,have onlyrecently gained widespread use.They utilize the principle ofmagnetic field measurement and consist of a magnetic fieldgenerator and magnetic sensors.Essentally,a magnet is mountedon the motor shaft,rotating with the shaft.A circuit board with amagnetic field sensing chip in the center is mounted on the rearend cover.This chip measures the angle of the magnetic field,thereby determining the motor shafts rotational angle and angularvelocity.

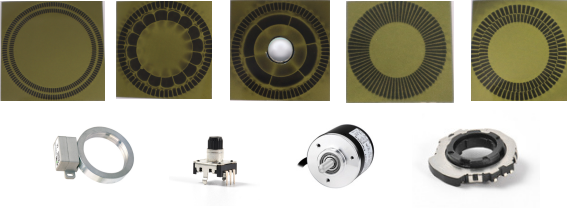

Magnetic Ring Classification | Appearance of Magnetic Ring | Magnetic Pole Display |

① Single-pole Magnetic Ring |

|

|

② Multi-pole Single-track Magnetic Ring |

|

|

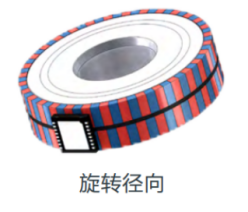

③ Radial Multi-pole Magnetic Ring |

|

|

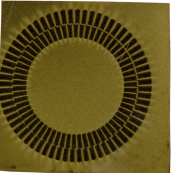

④ Multi-pole Dual-track Magnetic Ring |

|

|

⑤Triple-track Magnetic Ring |

|

|

Our company specializes in customizing multi-pole magnetic rings for Hall sensors and magnetic encoders. Welcome to consult!

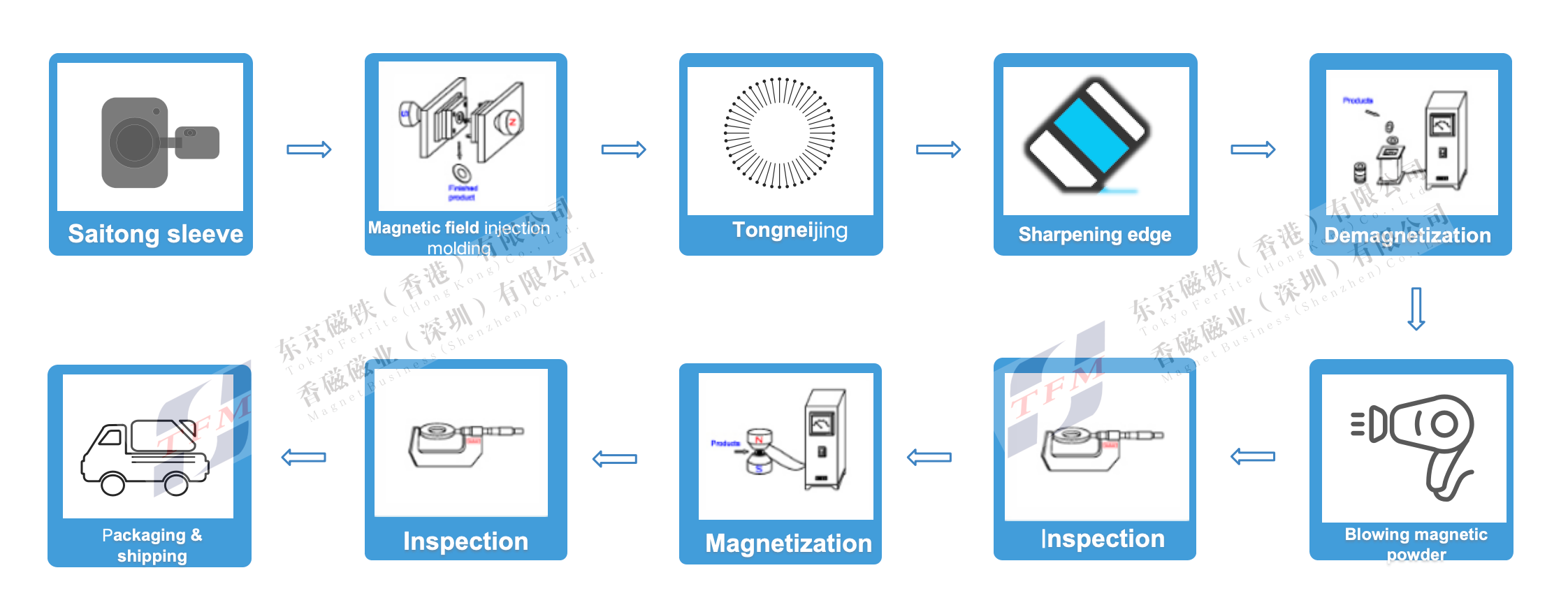

1. Multiple Material Options

Supports materials such as injection molded ferrite, sintered ferrite, rubber magnet and bonded NdFeB to meet different application requirements.

2. Flexible Magnetization Direction

Axial, radial or planar magnetization can be selected to meet various design and installation requirements.

3. High Pole Design

Magnetic rings with up to 400+ poles can be designed as needed to support complex magnetic field requirements and precise position detection.

4. Multiple Track Options

Single, dual, or triple channel configurations can be selected to meet the accuracy and resolution requirements of specific applications.

5. Adjustable Magnetic Strength

Depending on the selected magnet material and number of poles, magnetic strengths ranging from 0 to 100mT are available to meet the accuracy and sensitivity requirements of different applications.

6. Diverse Magnet Forms

Including ring, disc, square and other special-shaped magnets to adapt to various installation spaces and mechanical layouts.

7. Widely Applicable Fields

It is mainly used in motors, encoders, Hall sensors, magnetic transmissions, magnetic wheels and other fields, providing accurate position and speed detection functions for various electronic and mechanical equipment.

No. | parameter | MTA (Axial Type)

| MTR (radial type)

| MTL (Linear Type)

|

1 | Product Specifications | Customizable performance in any size | ||

2 | Number of Poles | 64/63 pole pairs; 32/31 pole pairs; 16/15 pole pairs, etc. | ||

3 | Number of Tracks | Sngle/Dual/Triplei | ||

4 | Application Scope | Magnetic Encoder | Magnetic Scales | |

5 | Limiting Speeds | Linear speed up to 16 m/s; Rotate speed up to 24,000 RPM @ 16 pole pairs Rotate speed up to 12,000 RPM @32 pole pairs; Rotate speed up to 6,000 RPM @ 64 pole pairs | ||

6 | Operating Temperature Range | - 40-110℃ | ||

7 | material | Injection molded ferrite/sintered ferrite/rubber magnet/bonded NdFeB | ||

8 | Magnetization method | axial magn etization | Radial magnetization | Planar magnetization |

9 | Magnetic strength | 0-100mT | ||

10 | Minimum Pole Spacing | 0.1mm | ||

11 | Maximum Number of Magnetization Poles | More than 400 poles | ||

12 | Peak Deviation | ±1% | ||

13 | Interpolar Phase Deviation | ±1% | ||